Latest News

Meet Our Apprentice: Helping shape the future of Wilks

Twelve months ago, we welcomed a bright and energetic apprentice to join the Flexiteek group – just in time for the exciting launch of Flexiteek 3. Working with Colchester Institute, Riley began a four-year Machining Technician Level 3 Apprenticeship, aiming to develop his manufacturing and engineering skills through hands-on learning.

After completing his first year, we are celebrating his achievements, reflecting on the value of apprenticeships, and looking ahead to what’s next.

Apprentice Spotlight: Meet Riley

Meet Riley, our Apprentice Toolmaker, who has just finished up his first year in his Toolmaking apprenticeship at our global headquarters and what a year it’s been. In a short time, he’s developed an impressive range of practical skills and become an integral part of our team. His dedication and drive have been incredible.

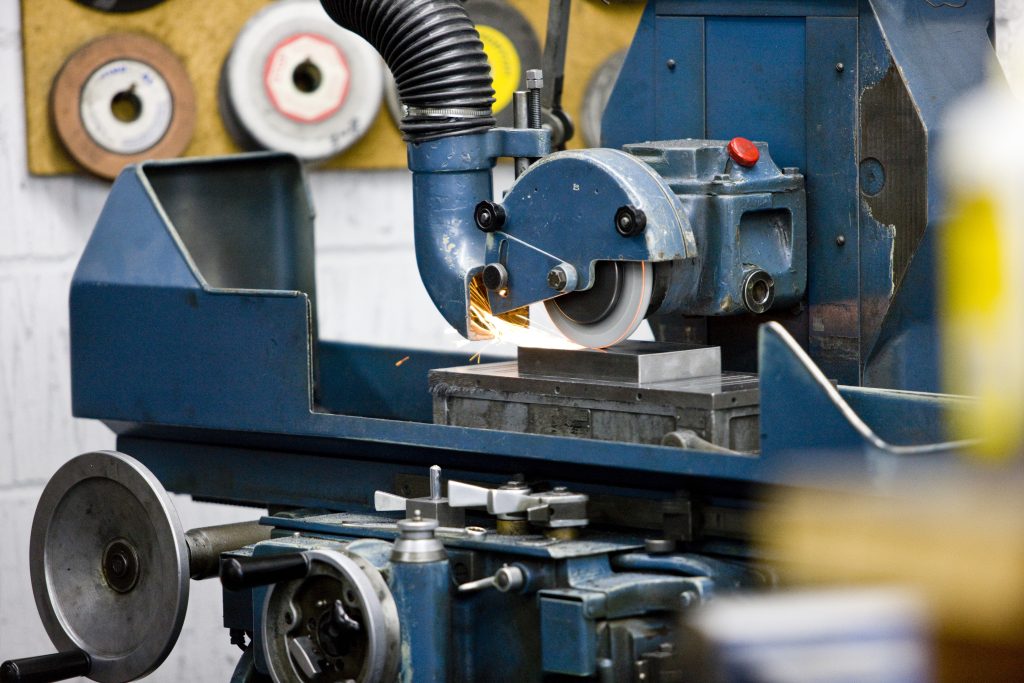

Throughout the year, Riley has successfully completed all his apprentice workbooks, showing a good comprehension of the theoretical side of toolmaking. He also excelled in his health and safety assessments, proving he takes safety in the workshop seriously. On top of this, he’s built a strong foundation in essential hands-on techniques, settling into the fast pace of a busy tool room with ease.

Riley reflects on his first year of his apprenticeship :

“My confidence has improved greatly in operating machinery and the 2D design systems compared to where I started.”

Riley has wasted no time getting to grips with complex tools and techniques. He can now confidently produce a clamp ring on a lathe from start to finish—a fundamental operation in toolmaking. He’s also mastered the duplication of existing tools, a crucial skill for creating Wilks profiles as well as supporting the development and launch of Flexiteek 3.

Riley has become a real asset to the tool room and assists our Engineering & Product Development Manager. From refining tooling for Flexiteek 3, creating Wilks products to supporting day-to-day operations, Riley has become an indispensable member of the tool room team.

Steve, our Engineering & Product Development Manager, adds :

“Riley has progressed and learnt so much from when he started working for Flexiteek.”

We’re incredibly proud of Riley’s progress and the energy he brings to the team. We can’t wait to see what he’ll accomplish next.

What is the Importance of Apprenticeships?

Apprenticeships have long been a cornerstone of hands-on learning in skilled trades, but today, they’re more essential than ever. In an evolving manufacturing landscape, where advanced techniques and technologies are constantly emerging, the need for skilled, adaptable professionals is critical. That’s where apprenticeships step in, offering a real, practical solution.

For individuals like Riley, an apprenticeship provides the best of both worlds: the opportunity to earn a wage while working towards a nationally recognised qualification. It’s a path that builds confidence, sharpens technical expertise, and fosters personal growth. Apprentices learn not just how to do the job but also how to thrive in a professional environment, developing communication, problem-solving, and teamwork skills along the way.

From an employer’s perspective, apprenticeships are more than just training schemes; they are a smart investment in the future. At Flexiteek, we found Riley brought a fresh energy, curiosity, and a willingness to learn. Within just a year, Riley has contributed meaningfully to a major product launch and has already started carving out a valuable role within the team.

Looking at the bigger picture, apprenticeships support industry-wide resilience. They close critical skills gaps, provide a clear succession pipeline, and ensure that technical knowledge is passed down to the next generation.

Working with Colchester Institute

Working with Colchester Institute has played a vital role in supporting Riley on his journey into the industry. Now completing his first year of the Machining Technician Level 3 Apprenticeship, Riley has covered key areas such as engineering principles, environmental health and safety, as well as hands-on training in preparing and using lathes for turning operations and milling machines.

The course offers a balanced mix of classroom learning and real-world experience in our workshop, allowing Riley to immediately apply his new skills in a practical setting. This combined approach is helping him build confidence, gain a nationally recognised qualification, and contribute meaningfully to our team. Learn more about the course here.

What’s Next for Riley?

As Riley enters his second year, he’ll begin tackling more advanced skills to build on his strong foundation. He’ll train in 2D CAD design, engineering maths, and CNC milling, gaining the tools to handle complex projects with greater precision.

He will also begin learning CNC programming and CAD/CAM systems, expanding his capabilities from manual machining to digital manufacturing. These skills are vital for staying competitive in today’s high-tech workshop environment.

Alongside technical growth, Riley will take on more responsibility in live projects, deepen his problem-solving skills, and continue contributing to product development. With continued support and mentoring, he’s well on his way to becoming a skilled, confident toolmaker.

Final Thoughts

We’re incredibly proud of everything Riley has achieved in his first year as an apprentice. His enthusiasm, work ethic, and willingness to learn have made a real impact on the team, and we’re excited to see how he continues to grow in the next stage of his journey.

Riley reflects on the coming year :

“I am looking forward to to bettering my skills in 2D design work for the tooling as well as the process to help to make a better product.”

Apprenticeships like Riley’s are a powerful reminder of the value of investing in young talent, bringing fresh energy into the business while building skills for the future.

Congratulations, Riley – we look forward to what’s ahead!